Quality Features

1. Each thread of the roll-formed steel pipe nipples is complete, full, smooth, and continuous.

2. Each tooth surface is smooth and clean, resembling a grinding surface.

3. The tooth shape and taper are 100% satisfactory, and the products are free from any defects.

4. The thread size and concentricity at both ends are identical, and the thread quality remains consistent during mass production.

Performance Features

1. For galvanized steel pipes, the galvanized layer on the roll-formed pipe threads is generally preserved, preventing rusting of the threads. Therefore, there is no need for on-site anti-rust protection, such as oiling.

2. For galvanized steel pipes, rolling preserves their galvanized layer and compresses it with the zinc-iron alloy layer, resulting in enhanced anti-corrosion performance for the threaded section. This enhancement significantly improves the lifespan of the joint, making it as long-lasting as the original galvanized steel pipe.

3. After the rolling process, the metal grain density of the threaded section increases by at least 2 levels. Additionally, the surface hardness of the thread increases by 30% or more, resulting in improved fatigue resistance strength compared to the original steel pipe. The tensile and shear strength of the threaded section is equal to that of the original steel pipe. Furthermore, the bending strength of the threaded section is 75% of the standard (90°) bending strength of the original steel pipe.

4. The lifespan of the rolled pipe thread joint is equivalent to that of the steel pipe, thereby significantly extending the lifespan of the pipe network.

5. The mechanical performance of the rolled threaded connection pair is essentially equivalent to that of welded connections in steel pipes.

Installation Features

1. Save 80% or more on sealing tape during installation.

2. There is no need to perform anti-corrosion treatment on the exposed threads after installation.

3. The rolling pipe thread can be tightened using a tool by only 1.5 to 2 turns to achieve a complete seal of the internal and external threads.

4. The surface of the thread is highly smooth, resulting in low friction resistance when tightening. It does not stick or spot weld between the threads, allowing for efficient one-time tightening.

5. The threaded engagement connection lengths at both ends are equal, and the installation length is easily manageable.

6. The thread size at each end is the same, and the tightening torque can be standardized.

7. Achieve 100% success in the initial pressure test, thanks to the interlocking sealing of the thread itself, which eliminates the need for recall, disassembly, and rework.

8. While reducing the labor intensity of workers, the overall construction efficiency is greatly improved, and labor costs are significantly reduced.

Product Parameters

Steel pipe material: Welded carbon alloy steel pipe and seamless carbon alloy steel pipe, as per GB/T 3091, GB/T 8163, GB/T 17395, ASTM 106, ASTM A53, or similar

Pipe finish: Galvanized or Black

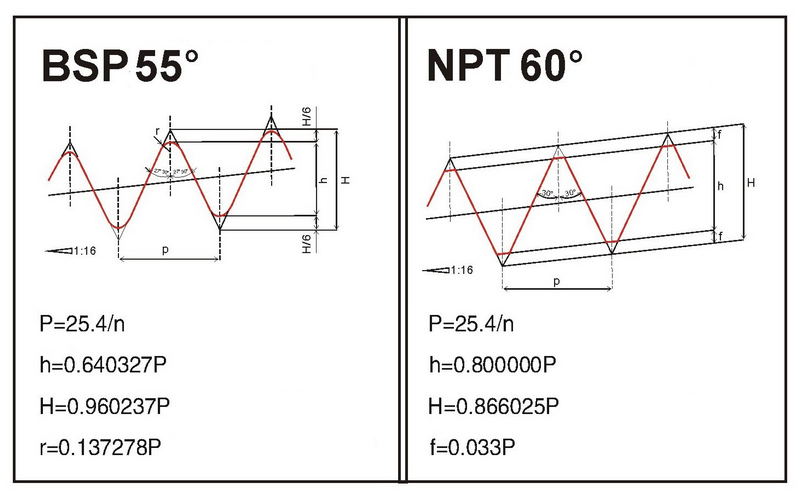

Thread standard: 55° BSPT and 60° NPT as per ASME B1 20.1, A733-03, BS EN 10241 GB/T 7306 GB/T 12716

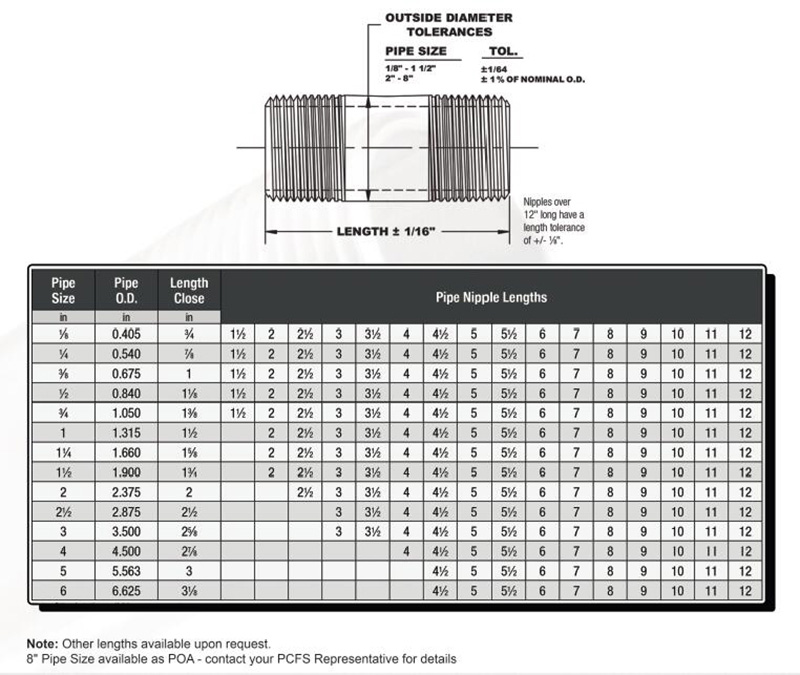

Pipe Dia. Size: DN8 ~ DN100, requirement beyond this diameter range needs further detailed discussion

Product length: Close ~ 6 meters ~ 12 meters ~ 18 meters

Pipe Thickness: Sch40 ~ Sch80 ~ Sch120 ~ Sch160